Alternative and Unique Uses for 3D Photogrammetry Scanning

There’s no denying how new technology can help in every avenue in life, especially for the AEC industry, which has seen a surgency in new tech. Every year, innovation is intended to make projects easier to design, simpler to manage, and less stressful during the entire process; and while these tools are meant to help, they do require a degree of effort by professionals. Therefore, it’s up to the AEC professionals to continue learn about new technologies and their different applications.

One such innovation is the use of 3D Photogrammetry scanning, and while 3D laser scanners are commonly used in the architecture, engineering, and construction industries, this is not the limit of their benefits. Just like innovation comes from thinking outside of the box, 3D photogrammetry scanning can help improve your business in a way that is beyond the scope of the normal. Read on to learn how other industries can use 3D scanning to benefit them:

Interior Design

1). Visualizing– Interior designing is all about creating a “theme” for a space and then developing that concept throughout the design of the space. However, before a new design for a space can be developed, a documentation of the current space would help with quantifying the parameters of the space. 3D photogrammetry scanning allows interior designers to visualize the space in its current state in order to begin testing different design decisions.

2). Accuracy of space– When designing a space, it is important to ensure that the intended design components “fit” properly into the space. Therefore, a designer should be certain that the design plans have a precise level of accuracy as to not waste time and money on inaccuracies. 3D photogrammetry scanning eliminates these errors and helps designers make confident design decisions.

3). Photorealistic Renderings – Once 3D scanning is finished and an accurate 3D as-built model has been created to begin the interior designing; the next level of presentation would be to 3D render the space to really bring the space to life. Photorealistic renderings usually take more time and cost more because a 3D model is needed for the process, however with 3D scanning a model is already a byproduct of the as-built process.

Virtual Reality

1). Reality Capture with Photogrammetry – 3D Photogrammetry scanning, unlike 3D photography, allows the image to have quantifiable data and depth. In other words, the “image” data is a virtual replica of real-world conditions. And, once all the data is “stitch” together, an entire 3D virtual environment is created that is identical to the current real-world conditions.

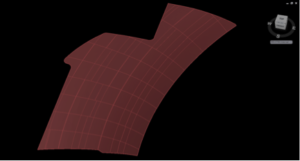

2). Data points to object “mesh”– There is a conversion process to take these points of scan data and develop them into a file type that is VR ready. It’s a process of taking the scan data and converting it into an Object File (OBJ file), which allows the image to overlay on the point to create a series of geometric surfaces (polygon mesh) usable for VR.

3). Video game experience– Unlike the old Xbox or PlayStation consuls that created the illusion of a 3D environment on the tv screen; todays Oculus and HTC Vive (along with others) provide a true VR experience. Wearing these devices allows a person to visually perceive and move around in those conditions as if playing avideo game (or more like being in one). This allows a person to experience that space in true VR fashion without every stepping foot inside that space, being miles away across the city or across the country.

Fabrication and Installation

1). Fitting pieces together– Whether your creating aircraft parts or building a home, making sure pieces fit together is a crucial piece. Before our ability to use 3D scanning, ensuring this meant either going through trial and error or hours of collecting detailed measurements. Even with the measurements, there was always a chance of miscalculation. By utilizing 3D scanning services, precisely fitting pieces are not only accepted, but expected.

2). Manufacturing detailed objects– If you’re manufacturing objects of varying detail, you may run into complications. The human eye can only see so much and “guesstimate” even less. With 3D scanning, you’ll see whether the product will work before you produce it, and the high resolution decreases the chances of flaws in design.

The limits of how 3D photogrammetry scanning can help you are endless. The innovation of 3D laser scanners has opened a door with more possibilities than we can possibly grasp right now. While these services have proven beneficial to the AEC industry countless times, that is not the limit of their usefulness. To learn how 3D laser scanning can benefit your project, call 1-888-585-5568.