Benefits of 3D Scanning

Imagine being a kid again and playing Legos with your friends. You have an idea of what you want to build, but you’re not sure if you’ll have enough pieces or that they will all fit. So you start building and spend a lot of time on your design. Unfortunately, you do run out of Legos and you can’t complete your project.

The architecture, engineering, and construction industry runs into this same dilemma. However, the process isn’t quite so simple. In the AEC industry, miscalculation and underestimations have drastic outcomes and everyone down the line pays the price of those mistakes.

And, while these costly circumstances still happen today, 3D scanning services have tremendously reduced their frequency and negative impact on a project. For this reason, and many more, 3D scanning services should be standard requirement on almost every AEC project.

The benefits of 3D scanning include:

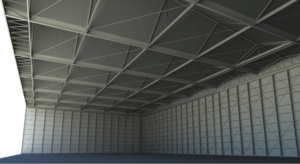

- Improved Planning and Design-Whether you are creating something from the ground up or doing a redesign, there has to be some sort of plan. You have an image in your mind of what you want for the final product—3D scanning allows you to understand what conditions you are actually working with. The collected 3D scan data can then be placed into a 3D modeling or computer aided drafting software for the virtual development of those existing conditions. This allows you to analyze new design elements, existing conditions, and evaluate any alternate design concepts quickly and easily because the information is all there.

- Enhanced Safety-There are health, safety, and environmental regulations that must be followed within the AEC industry. Failure to meet a criteria could mean being shut down. But these guidelines are created for a reason. In a lot of cases, they serve as a way to maintain safety. A miscalculation or unnoticed defect could mean you are creating an unsafe product or structure. 3D scanners are able to document those conditions, so a safety supervisor can assess the level of danger and take the necessary precautions.

- Greater Accuracy-The datasets created by 3D scanners have a high level of accuracy. Even with millions of data points registered together, this technology can capture complex dimensions and geometries to within a 1/16 of an inch (depending on the level of resolution and distance). The scan data can then be shared between all the different disciplines, so that everyone has the same set of accurate information to make design decision from.

- Reduced Time-This goes hand in hand with accuracy. Without 3D scanning services, there will be mistakes, and each one of those miscalculations means wasted time that it took to do the job and the additional time needed to redo it. Regular data collection methods (tape measurer, hand held laser, etc.) are also very time-consuming and not recommended for complex geometry or historic structures. 3D scanning technology, however, can survey a structure, record the data in a point cloud, and the as-built 3D modeling (or drafting) process of the structure can begin in a fraction of the time.

- Model Creation-Data collected by a 3D laser scanner can be exported to modeling and BIM programs to generate 2D CAD drawings or 3D models. Once the as-built model is developed, you the designer, can bring your concept to life and focus on developing that concept. Scanning technology frees the designer to focus on developing their design for the project instead of wasting valuable time modeling and existing conditions.

Whether you are creating something new, renovating, or redesigning a project, 3D scanning can help you. The AEC industry is constantly being transformed and scanning technology is allowing a part of this transformation to have a standard of efficient accuracy. If you have any questions on how you can incorporate 3D scanning services to your next project, contact us today.